🔍

🔍 🔍

🔍 🔍

🔍 🔍

🔍 🔍

🔍 🔍

🔍 🔍

🔍 🔍

🔍 🔍

🔍SwiftPress Vacuumformer

From $100

The SwiftPress was the first adjustable, non-membrane vacuum former specifically designed for use in the holster industry. By eliminating the silicone membrane found on other vacuum formers, the SwiftPress produces increased definition in the formed parts, and allows for drastically shorter cooling cycles.

—

Please note: SwiftPress and SwiftPress frames do not qualify for free shipping. All US SwiftPress orders will ship via UPS Ground

SwiftPress and SwiftPress frames do not qualify for free shipping.

All US SwiftPress orders will ship via UPS Ground

*FREE SHIPPING $100 (lower 48 states only)

Additional Information

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Press Package | Full Kit ($425), Adjustable frame ONLY ($100), Full kit (slight cosmetic blemish) ($375) |

The SwiftPress was the first adjustable, non-membrane vacuum former specifically designed for use in the holster industry. By eliminating the silicone membrane found on other vacuum formers, the SwiftPress produces increased definition in the formed parts, and allows for drastically shorter cooling cycles. The press is able to be plumbed directly to a vacuum pump without valves or surge tanks, and a pump with a capacity of 5cfm or more is recommended.

Using the SwiftPress

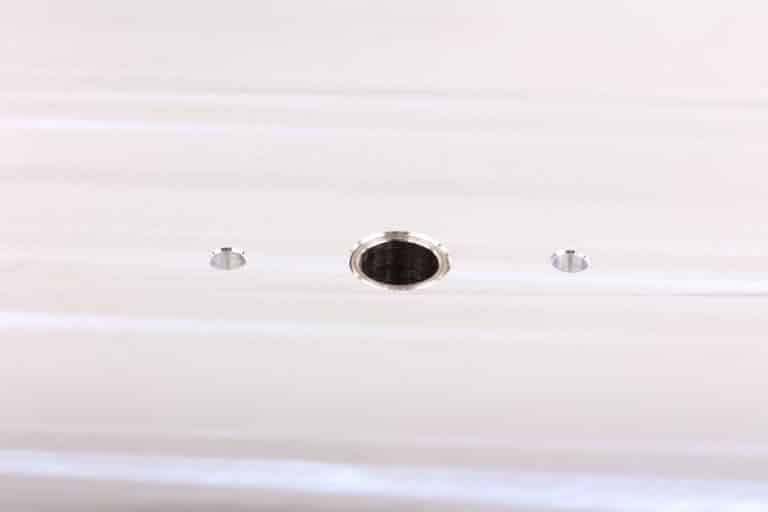

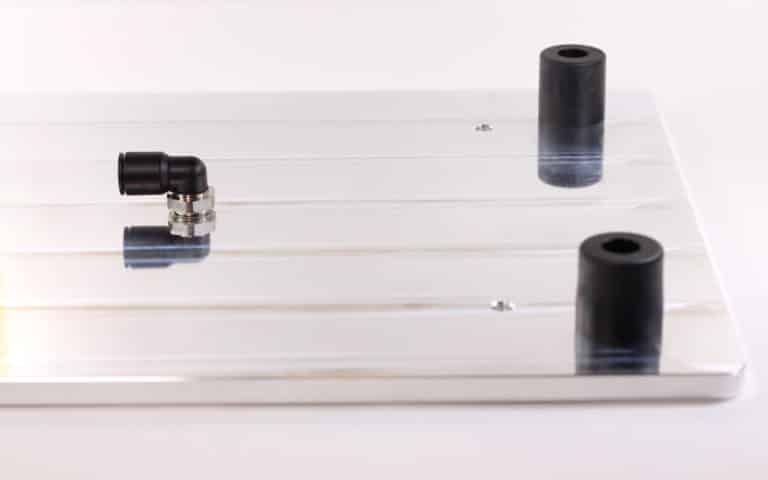

The sliding frame is adjusted to match the mold size by loosening one screw at each corner and then scaling the frame. The press comes equipped with a Push-to-Connect fitting for 1/2 OD vacuum line, which is also provided.

The forming deck measures 15x20in, with a max workable area of 14x19in. Placing multiple molds on the former for each cycle increases output, and also decreases plastic waste by allowing the molds to share edges.

Rubber feet on the underside allow easy access to the plumbing fitting, and the press can be unplugged for easy storage, freeing up valuable bench space when not in use.

Mold Setup

Included with the SwiftPress

Each press also comes with a roll of permeable Breather Mesh that should be cut down and placed under each mold to ensure even vacuum distribution to all the edges of the mold.

SwiftPress is ideal for medium to high-volume production of identical parts using split molds. Many customers find that a SwiftPress is an excellent complement to a membrane former, allowing them to run standard production items quickly on the Swift, while using the membrane former for custom printed plastics, curved-jig OWBs, and hybrid shells.

Each full kit includes the following components:

- A machined aluminum deck with a push-to-connect fitting installed.

- An adjustable frame made of 1 inch extruded aluminum.

- A 1/2NPT to Push-to-Connect fitting that can be installed on a Robinair 15800 pump. (the pump we recommend.)

- A length of vacuum rated line

- A roll of permeable breather mesh for you to cut up and place under your molds.

Warranty and Returns:

- The SwiftPress is covered by a 30 day return policy. Product must be in “like new” condition (no dings, dents, scratches). Please contact Henry Holsters before returning any product.

Chris (verified owner) –

Been using a ckk membrane former for about a year, just started using my Henry former and it was a total game changer. Significantly improved definition and much shorter cool down time on the kydex. Simple and easy to use. My only issue is that it came with 3/4″ push fittings, and I had to purchase a reducer because my vacuum pump had a 1/4″ outlet. No big deal, very plug and play. Would recommend to any bender wanting to step up their game from a foam press or membrane vacuum press.

Ron P (verified owner) –

freakin awesome way to get into vac molding without either having to build your own table or breaking the bank. I actually love this vac table haha the plug and play is the best part too. No headaches.